RCRA Corrective Action

Location: Middlesex, New Jersey

Regulatory Program: RCRA Corrective Action

Duration: September 2001 to Present

Summary: Streamlined Corrective Action project and Environmental Indicators assessment, CSM development and DNAPL delineation in fractured rock, making full use of existing data from adjacent site investigations, collaborative remediation of overlapping plumes.

This facility occupies four acres in a highly industrialized area. Site operations began in 1968, and have focused primarily on solvent recycling and blending of fuels for use in cement kilns. Additional activities performed during recent years include sale of virgin solvents and the repackaging and recycling of lab pack wastes. The facility handles much of the industrial hazardous waste produced in the northeast, and is New Jersey’s largest Large Quantity Generator under the RCRA program.

Based upon several short site inspections and limited sampling conducted previously at the site, USEPA identified six Solid Waste Management Units and three Areas of Concern (AOCs) to be addressed under RCRA Corrective Action, pursuant to a Hazardous and Solid Waste Amendments (HSWA) permit. The HSWA permit required the client to conduct multiple phases of field investigation and remedial assessment, including a Release Assessment (RA), a multi-phased RCRA Facility Investigation (RFI) and a Corrective Measures Study. For each of these work phases, the permit required submittal of draft and final copies of detailed work plans and reports.

Princeton Geoscience initially compiled an extended project schedule showing timelines for all project activities required under the permit, including work plan development, coordination with subcontractors, field activities, laboratory analyses, report preparation and regulatory review. Based on the schedule, it became evident that over two years would elapse before the extent of contamination in the shallow “perched zone” aquifer would be determined. This protraction of the schedule was associated mainly with the requirement to submit and revise cumbersome workplans before completing any work onsite, but the structuring of the work into artificially distinct phases and work areas also would have caused delay.

In addition, the delay would have been inconsistent with the RCRA Cleanup Reforms of 1999 and 2001, which are intended to speed the achievement of project goals by focusing on results rather than procedures, and by eliminating barriers to application of innovative and common sense solutions. Therefore, Princeton Geoscience proposed an alternate, streamlined approach to expedite the site characterization, which was accepted by USEPA and NJDEP.

Onsite drilling for monitoring well installation under the revised approach for the site characterization, the RA and RFI for soil and groundwater have been combined into three phases of work (RFI Phase 1, 2 and 3) and the investigation is taking place in a site-wide, rather than area- by- area, basis. In addition, Princeton Geoscience has prepared and submitted abbreviated workplans to USEPA and NJDEP for each phase, with minimal revisions to work scope required. An informal and efficient practice of regularly communicating project findings and obtaining input from the USEPA and NJDEP case management teams has been established, expediting the process and reducing costs.

Our findings have been conveyed officially in quarterly progress reports, with regular, face-to-face meetings at least at the conclusion of each phase of work in order to develop plans for future work in conjunction with the regulatory case team. The case team has accepted Princeton Geoscience’s proposal that, other than the quarterly progress reports, the findings of all three phases of the RFI can be submitted in one combined report at the conclusion of work, further expediting and lowering the cost of the project.

Another factor that has significantly benefited the project is the site’s location in a heavily industrialized area and the proximity of numerous sites undergoing environmental investigation and/or remediation. Princeton Geoscience performed NJDEP file reviews for 14 nearby sites listed on NJDEP’s Known Contaminated Sites List, obtaining a great deal of directly relevant information which is being used to satisfy Corrective Action requirements.

Through file searches Princeton Geoscience identified an existing network of offsite monitoring wells in the perched zone and bedrock aquifers, which have been used extensively in all three phases of the RFI, for groundwater hydraulic monitoring and sampling. The file searches also returned voluminous hydrogeologic characterization data (e.g., records of pumping tests, rock coring, geophysical logging, soil coring, hydraulic monitoring, capture zone analyses, etc.) and results of well searches, water supply evaluations, ecological assessments, focusing the scope of further investigations.

Arsenic residue from adjacent site within two months of submitting the abbreviated RFI Phase 1 workplan, a detailed chemical and stratigraphic characterization of soil and perched zone groundwater was completed onsite. This included collection of a total of 70 soil samples and 30 groundwater samples from a total of 33 direct-push (i.e., Geoprobe®) borings onsite. This investigation identified extensive chlorinated and non-chlorinated volatile organic compound (VOC) contamination in soil and groundwater beneath the concrete surface containment, consistent with historical use of the site as a solvent recycling facility since the 1960s. Within three months of receiving analytical results for the onsite work, a supplemental offsite investigation was completed which accomplished horizontal delineation of site-related VOC contamination in the perched zone aquifer and provided the basis for the selection of appropriate locations for the installation of permanent monitoring wells onsite and at selected locations offsite, to supplement the existing network.

Working closely with the USEPA case team allowed Princeton Geoscience to rapidly demonstrate achievement of goals for the two current Environmental Indicators (EIs), in advance of the 2005 goal. EIs are measures developed by USEPA pursuant to the Government Performance and Results Act of 1993, to gauge the progress being made to control contamination at corrective action sites. The Human Exposure EI (CA 725) determines whether contamination has been controlled so that it does not pose a danger to people, and the Groundwater EI (CA750) determines whether contaminant migration in groundwater has been controlled. With the information collected onsite surveying using GPS technology from file reviews and well searches, Princeton Geoscience was able to complete the EI determinations with additional data collection including indoor air and surface water sampling.

Other RFI Phase 1 activities included packer testing and geophysical logging of the site production well during a shutdown period when the well pump was replaced, a well search and water supply survey (receptor evaluation), preliminary work for an evaluation of indoor air quality, and the assessment of the extent of onsite impacts resulting from past pesticide manufacturing on the adjacent property.

RFI Phase 2 focused on the bedrock aquifer, and included the installation of nine bedrock monitoring wells, five of which were double-cased to minimize vertical migration of contaminated water and non-aqueous phase liquid (NAPL). Princeton Geoscience has continued to gage and profile NAPL presence onsite, and attempted several recovery techniques, which proved impracticable due to the complex hydrogeology.

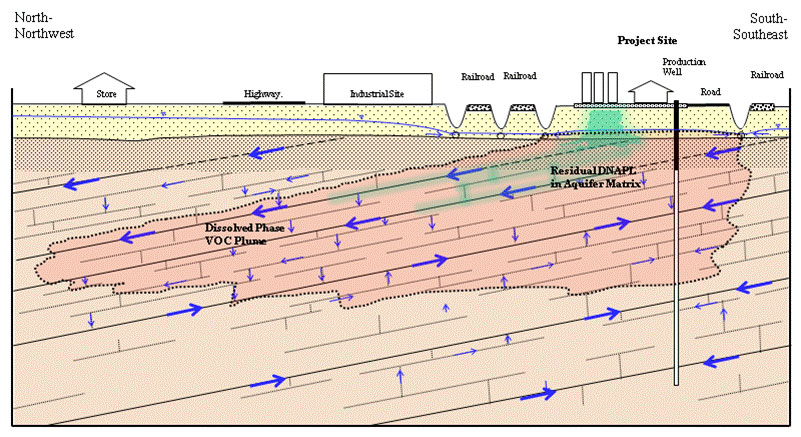

During the Phase 2 investigation, Princeton Geoscience determined that an existing bedrock groundwater extraction and treatment system remedy put in place pursuant to a 1980 Administrative Consent Order was not achieving its goal of preventing offsite migration of site-impacted groundwater. Vinyl chloride and several other chlorinated VOC were detected in fractured bedrock groundwater at concentrations of up to 9,000 ug/L, and similar compounds at lower concentrations were observed in water sampled from a production well on a downgradient facility.

Based on a review of site geology, results of pumping tests on adjacent sites, and consideration of new understandings regarding groundwater flow in the Passaic Formation that evolved subsequent to the ACO, Princeton Geoscience determined that the original remedy failed to capture this zone of contaminated water due to limited vertical interconnection among aquifer sub-units and the stratigraphic separation between the open-hole portion of the onsite production well (which served as the sole recovery well) and the zone of contamination.

During Phase 3, Princeton Geoscience implemented pumping tests, performed modeling and applied for a Water Allocation Permit (WAP) to allow an increase in onsite pumping above 100,000 gallons per day, as part of a planned upgrade to the ongoing groundwater remedy. The pumping tests showed that the remedy could be modified to achieve its goal by pumping one additional recovery well, sited based upon stratigraphic position and proximity to high-concentration portions of the plume. Modeling confirmed that long-term operation of the wells at the planned increase rate would not negatively affect offsite receptors and water supplies and would achieve the desired plume capture. NJDEP subsequently approved the hydrogeologic report that accompanied the permit application and issued a WAP for this site. Princeton Geoscience worked with contractors to modify the groundwater collection system to include a second recovery well, revise the air permit and begin operating the upgraded system. Interim results indicate that the modified system has significantly improved VOC capture and mass removal.

Onsite surveying using GPS technology other Phase 3 activities that are currently in progress include performing offsite soil sampling to support a Deed Notice; evaluating potential source reduction options for this active facility; delineating dissolved phase VOC and dense, non-aqueous phase liquid (DNAPL)-related impacts in the bedrock aquifer; and working with an engineering firm to assess the case for pursuing a Technical Impracticability (TI) Waiver from the groundwater restoration requirement.

Another challenging aspect of this project is that a contaminant plume originating on adjacent upgradient and side gradient properties is co-mingled with the area of site-related groundwater impact. The party responsible for this overlapping plume determined that the current operation of our client’s bedrock groundwater remedy results in hydraulic control of the pesticide-impacted groundwater originating from their site. The same property owner has installed a remedial system downgradient of both sites, designed to capture and treat pesticide-contaminated groundwater in the perched zone. The system layout is such that all perched-zone VOC contamination emanating from our client’s site is captured, and the system operators are treating for VOC removal as a condition of their POTW discharge permit. Because both remediation systems are expected to operate for many years, and the companies have had an excellent working relationship, the two companies decided to collaborate in their remedial efforts. Princeton Geoscience assisted counsel in developing a flexible and equitable approach that accounts for the need to establish and monitor institutional and engineering controls, and provide biennial certification ensuring continued protectiveness.